Discover the ins and outs of customizing and wholesaling silicone products in our comprehensive guide. Get all your answers here.

How to find an ideal silicone supplier? When considering the procurement in China and branding of silicone products for resale in your own country, you may have several questions and concerns. This process can be complex, but when properly planned and executed, it offers substantial opportunities for your business. In this guide, I will walk you through the steps and decisions necessary to ensure success in your journey of procuring and selling silicone products.

You might be wondering about the following:

- Wholesale or customized silicone products?

- Which silicone product is the most profitable?

- Where can I find quality suppliers?

- How to vet suppliers’ backgrounds?

- How are silicone products made?

- What are the specific steps for customizing branded products?

- How to ensure product quality?

- What is the logistics process?

In the upcoming sections, we’ll delve deeper into each topic and address these questions to help you establish a strong foundation for achieving your goals.

Wholesale or Customized?

When considering the procurement of silicone products, the first step is to plan your procurement strategy wisely. You can choose between wholesale silicone products that are readily available or opt for custom development of entirely new products. These two approaches have significantly different handling methods and come with their respective advantages and disadvantages.

The comparison table below can help you quickly understand the differences between the two methods.

| Aspect | Wholesale Silicone Products | Custom Silicone Products |

| Pros | – Quick to Market: Reduces time to market | – Uniqueness: Products stand out as unique |

| – Lower Costs: Benefits from economies of scale | – Meet Specific Demands: Can be tailored to market needs | |

| – Market Validation: Low-risk choice | – Brand Consistency: Builds brand recognition | |

| Cons | – Lack of Uniqueness: Hard to differentiate | – Higher Costs: Requires more initial capital |

| – Limited Customization: Restricted custom options | – Longer Production Time: Takes more time to develop | |

| – Risk: Uncertain market demand may lead to financial loss |

We can make a detailed comparison:

Wholesale Silicone Products:

Advantages:

- Quick Time-to-Market: Wholesale products are typically already manufactured, allowing you to introduce them to the market rapidly, reducing time-to-market cycles.

- Lower Costs: Mass production can lower the cost per unit, as costs are spread across more units.

- Market Validation: If you are unsure about the market demand for a particular type of silicone product, wholesale is a low-risk choice, as you can test market reactions without the need for large-scale custom production.

Disadvantages:

- Lack of Uniqueness: Wholesale products are generally more common and challenging to stand out in the market since many other businesses may have access to the same products.

- Limited Customization: You typically cannot make extensive customizations to wholesale products, which may limit your ability to meet specific market demands.

Custom Silicone Products:

Advantages:

- Uniqueness: Custom products can align perfectly with your specifications and brand requirements, making you distinct in the market.

- Meeting Specific Needs: You can customize products to meet unique requirements of your target market.

- Brand Consistency: Custom products help in building brand consistency and enhancing brand recognition.

Disadvantages:

- Higher Costs: Custom development usually involves higher initial costs, including mold development and pre-production preparations.

- Extended Production Time: Custom products take more time for design, development, and production, potentially causing delays in reaching the market.

- Risk: If the market is not interested in your custom product, it may result in financial losses.

Ultimately, the choice between wholesale and custom silicone products will depend on your business objectives, available resources, and market demand.

If you aim to quickly enter the market, cost control is crucial, or market validation is needed, wholesale might be a prudent choice. However, if your goal is to build a unique brand, cater to specific needs, and you are willing to bear higher risks and investments, custom products may be better suited to your needs. Greater returns come with greater investment and risk.

What products are profitable?

Currently, the relatively mature silicone product categories on the market include silicone ice trays, silicone lunch boxes, silicone feeding sets, etc. This can serve as your investment reference. In addition, there are some silicone products that have not yet been developed, which are also new business opportunities.

Before you start purchasing or customizing silicone products, you must first have a comprehensive understanding of the product and market. If you are a newbie, the following content will help you quickly and comprehensively understand the silicone product market.

Market Demand and Trends:

- Product Categories: Identify the specific categories of silicone products that are currently in high demand. Well-known products include silicone feeding supplies, silicone kitchenware, silicone phone accessories, etc. Keep an eye on trends and consumer preferences within these categories. You can get quantifiable sales data through Amazon or Google Trends.

- Consumer Behavior: Study the behavior of potential consumers. What factors influence their choices? Are they looking for durability, ease of maintenance, or environmental sustainability in silicone products? Understanding consumer motivations is key. There is a very simple and effective survey method – user reviews of target silicone products on large retail e-commerce platforms.

- Seasonal Variations: Certain silicone products may have seasonal demand fluctuations. Recognize these patterns and plan your procurement accordingly. For example, silicone ice cube trays may see increased demand during the summer months. By following this rule, you can achieve customer traffic and sales that far exceed expectations.

Customer Segmentation:

- Target Demographics: Define your target demographics. Are your silicone products aimed at young professionals, families, athletes, or a specific age group? Understand the specific needs of your customer segments. For instance, if targeting parents, consider safety features for child-friendly silicone products. Tailor your product features and marketing efforts to align with these demographics.

- Geographic Focus: Customers in different countries have varied buying habits when it comes to silicone products. Particularly in Europe and North America, customers prioritize the biocompatibility and eco-friendliness of silicone products, often showing less sensitivity to their relatively higher prices. This consumption pattern is not as prevalent in third-world countries.

- Distribution Channels: Determine the most effective distribution channels for reaching your target audience. Will you sell through e-commerce platforms, physical stores, or a combination of both?

Market Competition:

- Competitor Landscape: Identify key competitors in your chosen silicone product category. Explore their product portfolios, pricing strategies, and customer reviews. Look for gaps or opportunities in the market that you can exploit.

- Unique Selling Proposition (USP): What sets your silicone products apart? It could be superior quality, innovative design, eco-friendliness, or affordability. Define your unique selling proposition to attract customers.

- Local Regulations: Investigate the legal landscape in your target market. Are there specific regulations governing the manufacturing, sale, or use of silicone products? Be prepared to meet these standards to avoid legal complications. Some markets may have stringent quality requirements for consumer goods. Familiarize yourself with these standards, ensuring that your products meet or exceed them.

Which country to choose as a supplier?

When selecting a silicone product manufacturer as your supplier, it’s crucial to consider three key factors: profit margin, product quality, and a stable and reliable supply chain. Let’s briefly compare a few countries based on these criteria:

| Criteria | China | India | Western Countries |

| Profit Margin | High | Competitive | Lower |

| Product Quality | Varies (selective) | Variable | High (consistent) |

| Supply Chain Reliability | Reliable | Potential issues | Reliable |

| Overall Ranking | 1st | 2nd | 3rd |

China:

- Profit Margin: China ranks high due to its cost-effective manufacturing, offering substantial profit margins.

- Product Quality: Quality can vary, but China has well-established manufacturers capable of producing high-quality silicone products.

- Supply Chain: China’s supply chain is generally stable and efficient, making it a top choice for reliability.

India:

- Profit Margin: India can offer competitive pricing, providing a reasonable profit margin.

- Product Quality: Quality standards may not be as consistent as in China, requiring careful supplier selection.

- Supply Chain: India’s supply chain may not be as robust, potentially leading to some reliability issues.

Western Countries (e.g., Europe and North America):

- Profit Margin: Western countries generally have higher production costs, resulting in lower profit margins.

- Product Quality: High product quality is a hallmark of Western manufacturing, but this can come at a premium price.

- Supply Chain: Supply chains in Western countries are reliable but can be more costly and less flexible.

Based on these factors and ranking, China stands out as one of the best choices. Its extensive silicone product manufacturing industry, combined with reasonable infrastructure, makes it a viable option that balances cost-effectiveness with quality and supply chain reliability. Of course, the actual choice of supplier will depend on individual circumstances and specific supplier assessments.

Which platform has the best silicone suppliers?

When searching for suitable silicone product suppliers, it’s essential to consider the characteristics of silicone products and analyze the advantages and disadvantages of different search methods.

1. B2B platforms

B2B platforms like Alibaba or Made in China offer a wide range of choices, catering to various silicone product needs. You can easily filter suppliers based on criteria such as product type, company scale, and geographic location. Communication with suppliers is facilitated through the platform’s online messaging system, making business negotiations convenient.

However, this approach presents supplier diversity, as company sizes and capabilities vary. In other words, the barriers to entry for B2B platforms are usually not very high. Most companies that do not have the ability to build and operate their own official website will appear here. This results in potentially significant uncertainty regarding their production capabilities. You need to put more effort into conducting background checks.

2. Search Engines

The search engine (like Google) algorithm is very trustworthy. It determines rankings based on user search feedback and comprehensive evaluation of website content, so you can be assured of finding many high-quality manufacturers in the top search results.

On the other hand, using search engines for silicone product supplier searches also provides extensive information, including various suppliers and market intelligence. You can precisely search for the required silicone product information using specific keywords and filtering criteria.

The information may be scattered across different websites, necessitating time for organization and comparison.

3. Commercial Exhibitions

Participating in commercial exhibitions allows you to engage in face-to-face interactions with silicone product suppliers, building trust and gaining insights into their products. Moreover, you can inspect samples of silicone products to assess their quality and craftsmanship.

But the disadvantage is, the number of suppliers at trade shows is limited, potentially not meeting all your requirements, and attending such events may involve increased costs and time commitments.

In conclusion, if you lack experience in silicone product procurement, using search engines is a good option. It allows you to customize search criteria but demands extra care in verifying the reputation of silicone product suppliers.

In fact, at least 30% of Alibaba’s user traffic comes from Google. This means they are second-tier traffic dealers. Based on my past experience, compared with the information presented by companies on B2B platforms, the official websites of companies found through search engines will be more detailed. You’re more likely to get valuable supplier information.

As you gain a better understanding of the silicone product market, you can consider seeking suppliers on B2B platforms while also exploring commercial exhibitions, especially for establishing a more robust supply chain and building relationships.

It is always good to learn about suppliers through multiple channels. Regardless of the method you choose, ensure comprehensive background checks and due diligence to find reliable silicone product suppliers.

How to do background checks on suppliers?

After you find a supplier, you may want to have a deeper understanding. Here are some methods for your reference:

Company Qualification Verification

At its most basic, always make sure the supplier has the necessary licenses and qualifications to conduct the business you need. This includes certification for production, export and quality control. Require suppliers to provide relevant supporting documents.

Also ensure that suppliers comply with relevant regulations and legal requirements, especially those involving international trade and exports. Check whether they are affected by trade restrictions or sanctions.

Factory Visit

If possible, please visit the supplier’s production base in person for inspection. This allows you to see the supplier’s facilities and production processes first-hand and understand the manufacturing process and workmanship of the product.

This is undoubtedly the most effective method of investigation. However, considering the cost factor, you can choose to hire a factory inspection consultant in the country where the supplier is located to help you complete this work.

Other Means

Supply Chain Visibility: Understand your supplier’s supply chain visibility, i.e. whether they can provide transparency into the source and production process of silicone raw materials. This helps ensure product quality and sustainability.

Financial Stability: Suppliers’ financial status is reviewed to ensure they have sufficient financial stability to maintain production and supply. This includes reviewing their financial statements and credit history.

Trustworthiness and Reputation: Conduct online research to find out about the supplier’s reputation and reputation. Check reviews and reviews on industry forums, social media, and review sites for information about vendors.

These approaches can be used in combination to ensure that the supplier you choose is trustworthy, able to meet your needs, and maintains supply chain stability.

How much does custom production cost?

The cost of custom-manufacturing silicone products can vary significantly and does not have a fixed figure.

Typically include the following aspects:

Raw Material Costs: The choice and quantity of raw materials significantly impact costs. Different types and qualities of silicone raw materials come at varying prices. The color and specific characteristics of the silicone can also incur additional expenses.

Mold Costs: The molds required for manufacturing silicone products are usually an initial expense. This encompasses mold design and production. The complexity and size of the molds influence the cost.

Product Design Costs: If you require the supplier to provide product design services, this will add to the cost. The complexity of the design and the amount of engineering work needed affect the expenses.

Machine Setup Costs: In the case of low initial order quantities, the supplier may charge machine setup fees. This is to cover the time and resources required for setting up and adjusting the production line.

Product Manufacturing Costs: This includes the production process, labor, and machine usage costs for the silicone products. The size, shape, and complexity of the products will influence this part of the cost.

Product Packaging and Printing Costs: The cost of packaging materials, design, and label production should also be considered. The complexity of the packaging and printing requirements will affect these expenses.

The specific costs will vary based on the specifications, quantity, quality standards of the silicone products, and the pricing policies of the supplier.

What should you do?

The best practice is to have detailed discussions with potential suppliers regarding your specific requirements to obtain a quote tailored to your particular project. This ensures you understand all relevant costs, enabling you to make informed decisions. If you receive quotes from multiple suppliers, you can also compare them to find the most cost-effective solution.

You might be interested in some tips I put together:

You should clearly define the pricing structure in the contract, including the unit price of silicone products, volume discounts, mold fees, product design fees, equipment start-up fees and any other fees. This will help ensure you understand the impact of each part of the process on the price of the final product.

Understand that manufacturing costs may vary over time and volume. Include clauses in contracts on how price adjustments will be handled to avoid unnecessary uncertainty in supply chain management.

Mold fee for silicone products

In the custom manufacturing of silicone products, a large portion of the expense comes from the costs associated with product molds. Therefore, be sure to fully communicate this aspect with your suppliers during contract negotiations and pricing discussions.

Get a clear understanding of the manufacturing costs of silicone product molds from your suppliers. Make sure you understand how the cost of the mold is calculated (transparently and reasonably), including whether upfront payment is required and under what circumstances the mold may need to be updated or replaced.

Discuss mold ownership issues. Determine whether the mold belongs to the supplier or you, and determine what to do with the mold if the contract is terminated or the supplier changes.

Consider molding costs in your budget planning and make sure you allocate enough funds to cover mold manufacturing expenses. This helps prevent potential financial constraints later on.

Requesting Pre-Production Samples

When ordering custom products, especially unique ones, don’t skip requesting pre-production samples. They are your quality benchmarks for mass production. Some think it’s time and money wasted, but that’s a misconception.

You need to touch and feel the product to judge quality, not just rely on seller images. Investing time and effort upfront ensures a smoother delivery later. Trust me, it’s worth it.

I suggest getting samples from 2-3 suppliers. If one’s quality isn’t up to par, you have a backup. You can also request corrections for mass production. You’ll need to pay the sample fee upfront and shipping costs. It’s a small cost for quality assurance.

How are your products manufactured?

Here is a brief overview of the manufacturing process for silicone products:

Compounding and Mixing of Raw Material

The manufacturing process begins with the preparation of silicone raw materials. These materials are carefully measured and mixed to create the silicone compound with the desired properties, which may include color, hardness, and other specific characteristics. The silicone compound is then processed through compounding and mixing equipment. This step ensures that the raw materials are thoroughly blended to create a homogeneous mixture.

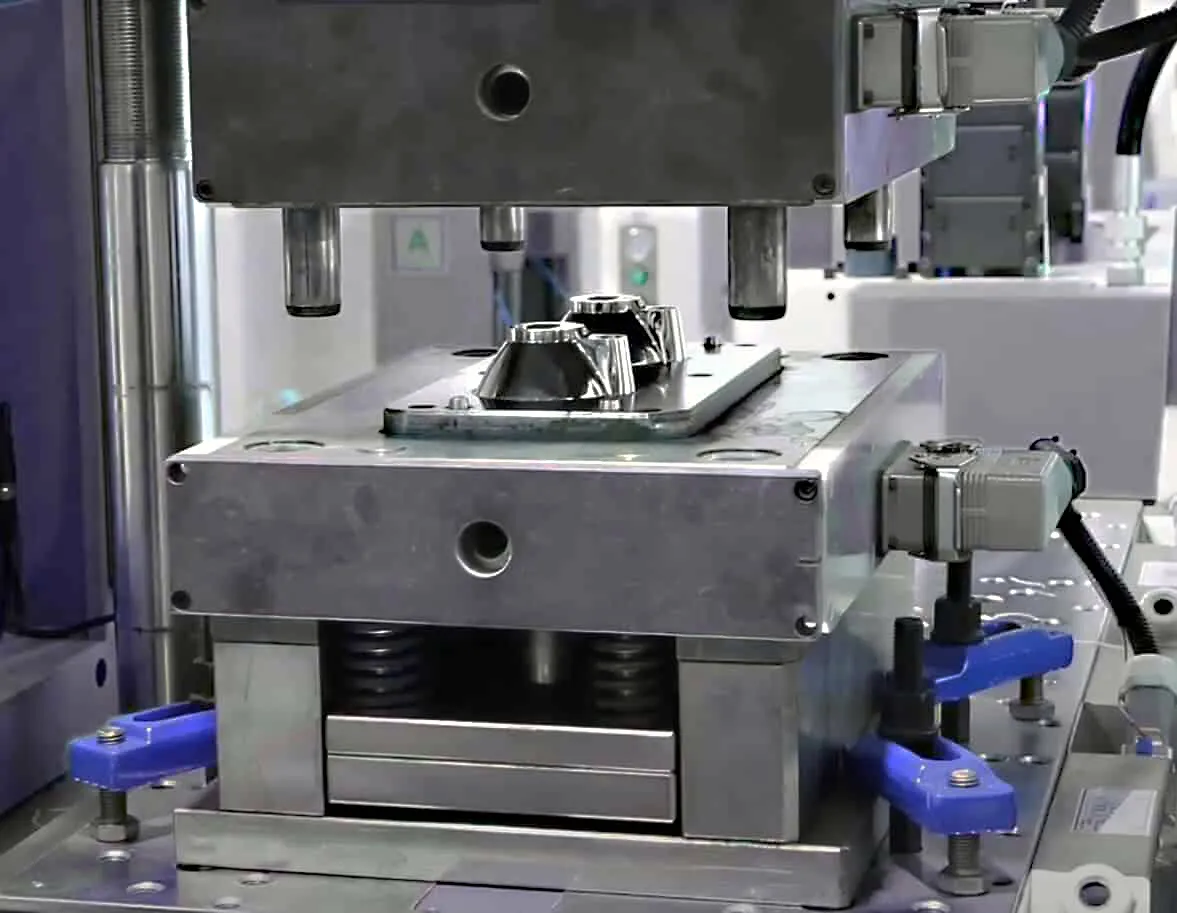

Injection Molding or Compression Molding

Once the silicone compound is prepared, it is fed into injection molding or compression molding machines. In injection molding, the material is injected into a mold cavity under high pressure to create the desired shape. In compression molding, the compound is placed in a mold cavity, and pressure is applied to shape the silicone into the desired form. These processes result in the formation of silicone products with specific designs and properties.

The manufacturing process may include additional steps, such as curing, post-processing, and quality control, depending on the specific requirements of the silicone products being produced.

Create completely unique silicone products

Competent suppliers can usually provide specialized brand customization services for your silicone products, including logo printing or engraving, custom pattern printing, and custom packaging design. These additional value-added services can help your silicone products stand out in the market and create a unique brand image.

Steps to creating your own brand of silicone products include:

- Preliminary process: During the design phase of silicone products, actively work with suppliers to tell them your brand values, vision and target market. Share your design ideas and basic requirements.

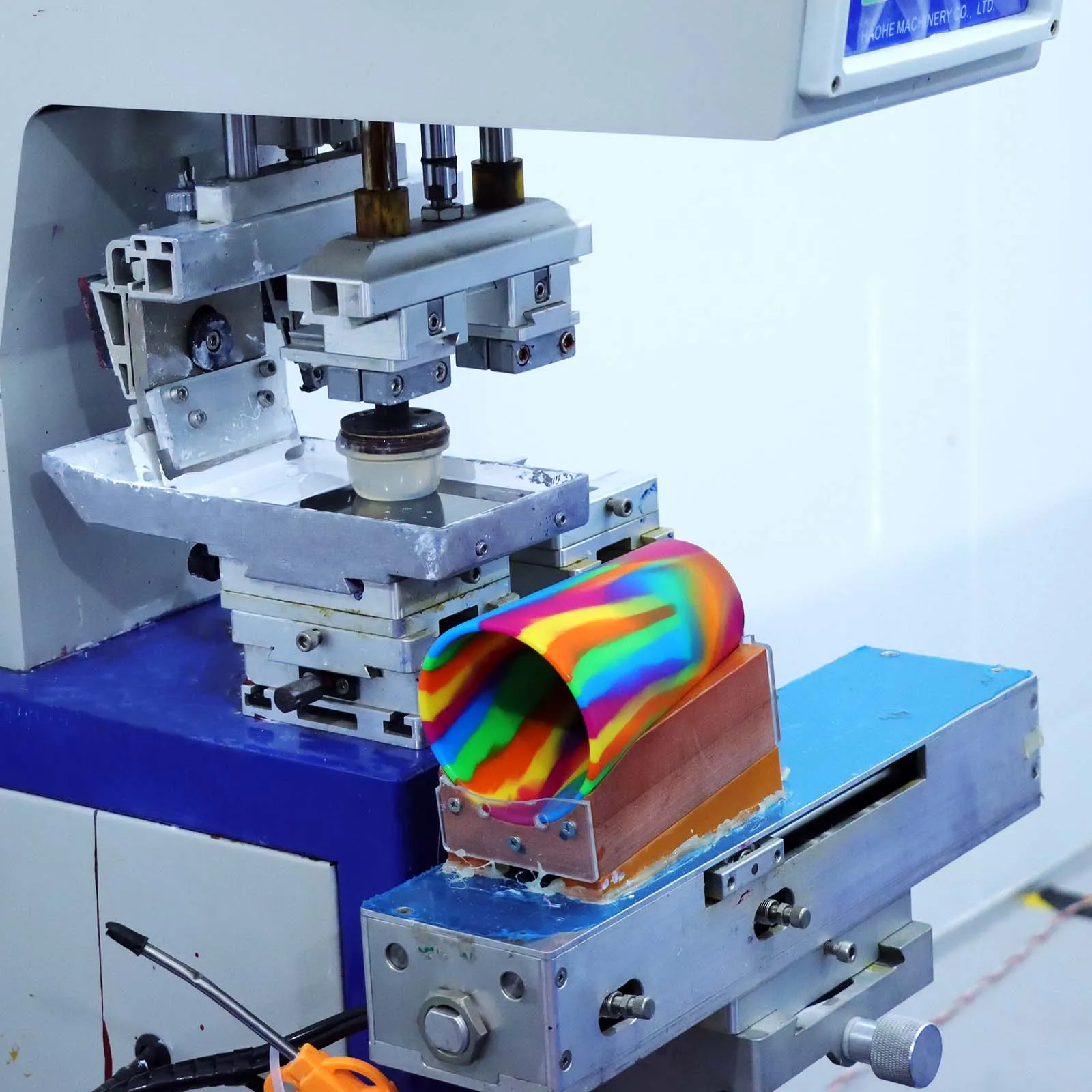

- Logo customization: Cooperate with suppliers to customize logos on silicone products. Their professional design team will create your logo for silicone products based on your guidance. They usually offer several designs for you to choose from. Common methods include laser engraving, silk screen printing, heat transfer printing, etc.

- Graphic Printing: If you wish to add a specific pattern to your silicone product, discuss this requirement with your supplier. They can help you print your design onto the product, ensuring its quality and durability.

- Packaging customization: In addition to the silicone product itself, packaging is also part of the brand. You need to provide packaging design direction and ideas for your products to ensure that the packaging is consistent with your brand image. You can review the final packaging design to ensure it aligns with market research and target market expectations.

These customized services can make your silicone products more attractive in the highly competitive market, establish a unique brand image, and attract consumers’ attention.

How to monitor product quality?

If you want your silicone products to reach a satisfactory level of quality before entering the market, you must work closely with your suppliers and take necessary review measures.

The following are the main aspects covering quality control and quality management:

Quality control begins by setting quality standards. Quality standards are clearly defined and set with suppliers at the beginning of the silicone product manufacturing process. Product specifications, quality requirements, performance parameters and testing standards are specified in the contract in detail. Ensure that suppliers are fully aware of these standards, and the quality standards will serve as a benchmark for silicone product manufacturing so that they can develop targeted production plans.

Quality control during the manufacturing process is a critical aspect. Implementing strict quality control measures at every step in the manufacturing process of silicone products can prevent problems in the bud. You need to ask suppliers to provide detailed information about the source of raw materials, production processes, equipment maintenance, and employee training. Review production processes with suppliers to ensure they meet pre-set quality standards. Through continuous process control, errors can be minimized and product quality improved.

Quality testing is an important means to ensure that silicone products meet quality standards. Contact suppliers and ask them to perform necessary quality inspections and tests at all stages of silicone product manufacturing. Discuss with suppliers the frequency, methods, and standards for inspection and testing. This may include dimensional measurements, hardness testing, tensile testing, temperature stability testing, etc. Understand the quality control techniques used by your supplier to ensure they are consistent with your expectations.

By adopting this consistent quality control and quality management process correctly, the quality and performance of your silicone products will be guaranteed.

Quality Problems

Although strict quality control measures and testing methods may reduce the occurrence of quality problems, quality problems may still occur. As a purchaser, respond proactively to any quality issues that arise. The key is to contact the supplier immediately to discuss the root cause of the problem and take corrective action.

This may include rework, re-production, process modifications, or changes to raw material suppliers.

Begin by promptly notifying the supplier of the problems and requesting a solution, whether it involves repairs, replacements, or refunds. Ensure that your requests are reasonable and align with the terms of the contract, which may outline quality standards, acceptance procedures, and dispute-resolution processes.

Simultaneously, collect evidence such as photographs, reports, and samples to substantiate your claims, which can be valuable in future negotiations or legal proceedings. If the issue remains unresolved, seeking legal counsel to understand your legal rights and potential legal avenues may become necessary.

In extreme cases where resolution is impossible, considering terminating the collaboration with the supplier while adhering to contract termination clauses, can be a last resort to minimize legal disputes.

Ultimately, it’s crucial to view quality issues as learning opportunities, conducting reviews of procurement and quality control processes to prevent similar problems in the future.

Third-party quality inspection

Engaging specialized quality inspection agencies to conduct product testing at the factory is a prudent approach to ensuring the quality and compliance of the products you intend to source. These agencies have the expertise and equipment needed to perform in-depth inspections, evaluate product specifications, and assess quality against agreed-upon standards.

However, it’s essential to be aware that while this method is highly effective in ensuring the product’s quality, it typically comes with relatively higher costs. These costs cover the fees for the specialized inspectors, equipment, and the comprehensive evaluation of the product. While it may be an additional expense, it can provide you with peace of mind knowing that the products meet the required quality standards and specifications. This investment in product testing can ultimately save you from potential quality issues, product recalls, or customer dissatisfaction down the line.

Questions about logistics

While logistics timing and costs are often handled by the supplier, you should maintain transparency and monitoring throughout the entire process to ensure everything runs smoothly.

Selecting Appropriate Logistics Channels

Typically, suppliers have long-term partnerships with reliable freight forwarders, who offer advice and support for product logistics and transportation. However, as a purchaser, it’s essential to ensure that you choose the right logistics channels to meet your delivery requirements. Collaborate with the supplier, understand their recommendations, and ensure that the chosen freight forwarder possesses the necessary experience and capabilities.

Handling Details of Sea, Air, or Land Transport

Logistics choices often include sea, air, or land transport. You need to balance time costs and economic costs to select the most suitable logistics method for your needs.

Let’s take a shipment to the United States as an example.

- Express Delivery (3-5 days): The Usain Bolt of shipping, is lightning-fast but pricier. Ideal for time-sensitive silicone products (like medical device parts).

- Air Shipping (4-7 days): A balanced choice, like a well-paced marathon runner, providing timely delivery without breaking the bank.

- Sea Shipping (25-35 days): The budget-friendly, long-haul option, like a cross-country trek with significant cost savings. (The choice of most customers)

In a nutshell, faster delivery costs more. Choose the method that aligns with your product’s urgency and budget. If you’re dealing with a substantial order volume, meticulous planning, and foresight are imperative. Discuss logistics plans with the supplier, including delivery times, cargo tracking, cargo insurance, and other details.

According to my experience, the time cost of silicone product development is mainly concentrated in the early stage. For later logistics, as long as a certain amount of time is reserved in advance, there will basically be no problems.