In the dynamic landscape of manufacturing, Liquid Silicone Rubber (LSR) and injection molding represent pivotal advancements that have transformed production processes. Originating in the 19th century, injection molding (a technique used to shape materials into their final form) revolutionized the mass production of parts, evolving from metal and glass to incorporate plastics.

Concurrently, the development of silicone rubber, and subsequently LSR, introduced materials with exceptional properties like heat resistance and flexibility. LSR, a high-purity, high-performance elastomer, boasts exceptional properties like flexibility, chemical resistance, and thermal stability. The integration of LSR with injection molding technology marked a significant leap, marrying the versatility of silicone with the efficiency of injection molding. It creates an alchemy of production that is both art and science.

A quick summary of the history of LSR and injection molding

The history of injection molding began in the 19th century, initially used for processing thermoplastics. With the invention of Liquid Silicone Rubber (LSR) in the 1970s, the technology advanced significantly. LSR’s integration into injection molding revolutionized the manufacturing process, allowing for the creation of complex, heat-resistant, and durable parts. Key developments included the introduction of precise temperature control and automated systems, enhancing efficiency and product quality. These innovations have made LSR injection molding indispensable in industries like medical, automotive, and consumer electronics, continuously evolving to meet the demands of modern manufacturing and setting the stage for future technological progress.

If you are interested, I will show you the specific content below:

The Origins of Injection Molding

Early History and Development of Injection Molding

Injection molding, a technique pivotal in manufacturing, has its roots in the late 19th century. Initially developed for producing billiard balls, which were formerly made from ivory, John Wesley Hyatt’s invention of a celluloid-based material led to the creation of the first injection molding machine in 1872. This machine was rudimentary, using a plunger mechanism to force the molten material into a mold. Despite its simplicity, this invention laid the groundwork for modern injection molding.

The early 20th century saw injection molding evolve to accommodate a broader range of materials, including metals. However, the process was limited by the technology of the time, which could not achieve the high pressures or precise temperature controls required for consistent quality. The development of screw injection machines in the 1940s, by James Watson Hendry, revolutionized the field. Hendry’s machine used a screw mechanism to better control the flow of plastic into the mold, allowing for more precise and consistent products. This innovation was a turning point, marking the beginning of injection molding as we know it today.

Transition from Metal and Glass to Plastics

The transition from metal and glass to plastics in injection molding was driven by the advent of synthetic polymers in the early 20th century. Materials like Bakelite, the first fully synthetic plastic, introduced in 1907, showcased the potential of plastics in manufacturing, offering advantages like moldability, lightweight, and corrosion resistance. As World War II necessitated the mass production of various goods, plastics gained prominence due to their versatility and cost-effectiveness.

Post-war, the demand for consumer goods surged, and plastics became the material of choice for a wide range of products, from household items to automotive components. The adaptability of injection molding to different plastics fueled its expansion, making it a cornerstone of modern manufacturing. Advancements in polymer science continued to broaden the capabilities of injection molding, allowing for the creation of products with complex geometries, varied colors, and enhanced properties like increased strength and heat resistance.

Key Inventors and Innovations in the Early Stages

Besides John Wesley Hyatt and James Watson Hendry, many other inventors contributed significantly to the evolution of injection molding. Alexander Parkes, who created Parkesine, the first man-made plastic, laid the foundational chemistry for future material innovations. Leo Hendrik Baekeland, the inventor of Bakelite, also played a crucial role by demonstrating the commercial viability of synthetic plastics.

These early pioneers set the stage for a century of innovation that would see injection molding become integral to manufacturing globally. Their contributions were not just in machine design but also in the development of materials and processes that enabled the mass production of a diverse array of products. As injection molding technology advanced, it became increasingly sophisticated, with computer-controlled systems and complex tooling that allowed for precision and efficiency on a scale previously unimaginable.

The Advent of Silicone Rubber

Discovery of Silicone and Its Properties

Silicone, a synthetic polymer, was first synthesized in the early 20th century, marking a significant milestone in materials science. Its discovery is attributed to English chemist Frederick Kipping, who worked on the chemical structure of silicones in the late 1800s and early 1900s. Silicone stands out from other materials due to its unique combination of properties, including thermal stability, chemical inertness, and electrical insulation.

Unlike carbon-based organic compounds, silicone possesses a backbone of silicon and oxygen atoms, a structure that imparts remarkable flexibility and heat resistance. These characteristics quickly made silicone a material of interest in various industrial applications. Its ability to withstand extreme temperatures and harsh environmental conditions, while maintaining its structural integrity and flexibility, positioned silicone as a superior alternative to more traditional materials like rubber and plastic in many specialized fields.

Development of Silicone Rubber

Silicone rubber represents a significant advancement in the broader category of silicone materials. Developed in the 1940s, silicone rubber combined the beneficial properties of silicone with the elasticity and malleability of rubber. This new material boasted exceptional heat resistance and durability, capable of operating in temperatures ranging from -55°C to +300°C, which far surpassed the capabilities of natural rubber.

The development of silicone rubber was a collaborative effort, with companies like Dow Corning and General Electric pioneering its commercial production. These companies innovated unique formulations of silicone rubber, tailoring its properties to suit various industrial requirements. The material’s superior performance in extreme conditions made it invaluable in sectors such as aerospace, automotive, and electronics, where reliable performance under stress is paramount.

Introduction of LSR and Its Advantages Over Traditional Silicone Rubber

Liquid Silicone Rubber (LSR) emerged in the 1970s as an evolution of solid silicone rubber, designed to meet the growing demand for easier processing and more intricate molding capabilities. LSR maintained the advantageous properties of traditional silicone rubber but in a liquid form, which allowed for more precise and efficient molding processes, such as injection molding.

The transition to LSR represented a significant technological leap. Its lower viscosity compared to solid silicone rubber meant that LSR could fill molds with more complex shapes and fine details, expanding the design possibilities for engineers and designers. Furthermore, LSR’s curing process, which occurs at room temperature under platinum catalysis, resulted in a faster and more energy-efficient manufacturing process. This process, known as addition cure, contrasts with the peroxide cure method used in traditional silicone rubber, offering advantages in terms of environmental impact and product purity.

LSR’s advantages extend to its mechanical properties as well. It exhibits excellent elongation, tensile strength, and tear resistance, which are maintained over a broader range of temperatures and conditions than traditional silicone rubber. These attributes make LSR an ideal choice for a wide array of applications, including medical devices, automotive components, and consumer goods, where performance and reliability are critical.

Integration of LSR with Injection Molding

The Technological Breakthrough

The integration of Liquid Silicone Rubber (LSR) with injection molding technology marked a significant milestone in the manufacturing industry. This breakthrough occurred in the late 1970s and early 1980s when companies like Dow Corning and Wacker Chemie began developing systems that could process LSR using injection molding machinery. The transition to LSR injection molding was driven by the demand for more efficient production of silicone parts, which were increasingly used in medical, automotive, and consumer products.

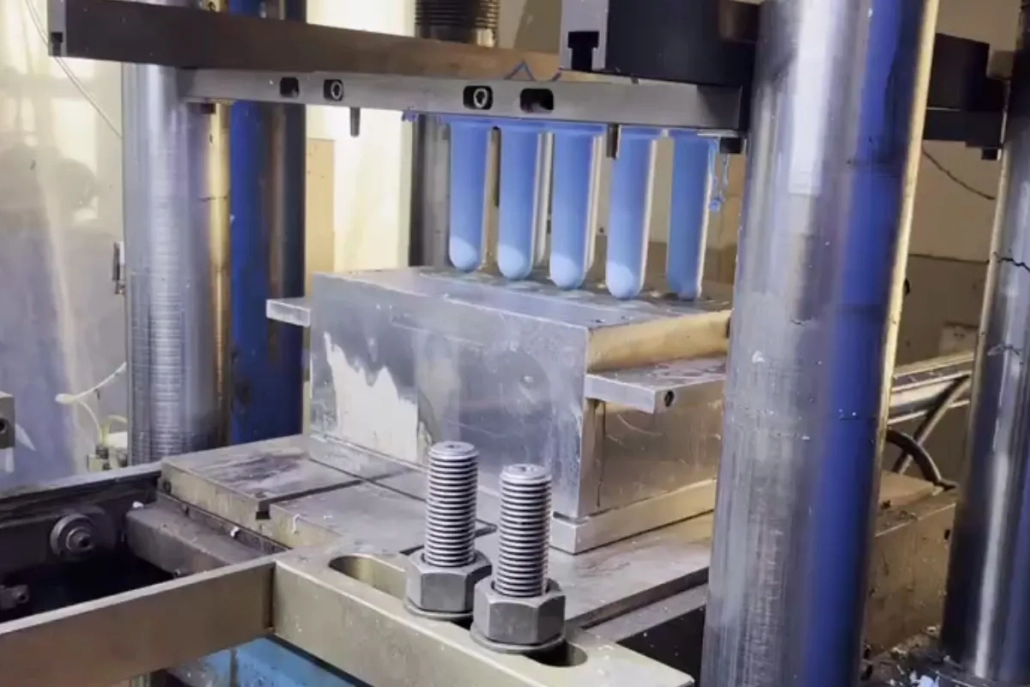

One of the key challenges in integrating LSR with injection molding was the material’s high reactivity and low viscosity. Unlike traditional silicone rubber, LSR could cure rapidly at elevated temperatures, necessitating precise control over the injection and curing processes to prevent premature curing and ensure uniform part quality. Companies had to innovate new machinery and tooling systems that could handle LSR’s unique properties, including specialized dosing equipment, heated molds, and dynamic mixing systems.

Another significant challenge was the development of a closed system that could prevent contamination of the highly reactive LSR components. The solution came in the form of advanced metering and mixing units that could accurately combine the two-part LSR material just before injection, ensuring both the purity of the material and the consistency of the final product.

Understanding the Process

The LSR injection molding process involves several key stages: material preparation, mixing, injection, and curing. Initially, the two-part LSR components (a base polymer and a catalyst) are stored separately to prevent premature curing. During the molding process, these components are precisely metered and mixed in a dynamic mixing unit, ensuring a consistent blend.

The mixed LSR is then injected into a heated mold, where it undergoes rapid curing. Unlike traditional rubber and thermoplastic injection molding, LSR’s low viscosity allows it to fill complex mold geometries with ease, capturing fine details and maintaining high dimensional accuracy. The curing stage in LSR injection molding is also distinct; it occurs much faster due to the material’s ability to rapidly cross-link under heat, typically within seconds to minutes, depending on the part size and design.

Comparatively, traditional rubber molding processes involve longer cure times and higher temperatures, while thermoplastic injection molding requires cooling of the molten plastic to solidify the part. LSR injection molding’s efficiency in both the filling and curing stages significantly reduces cycle times and enhances production throughput.

Mechanical and Technical Innovations

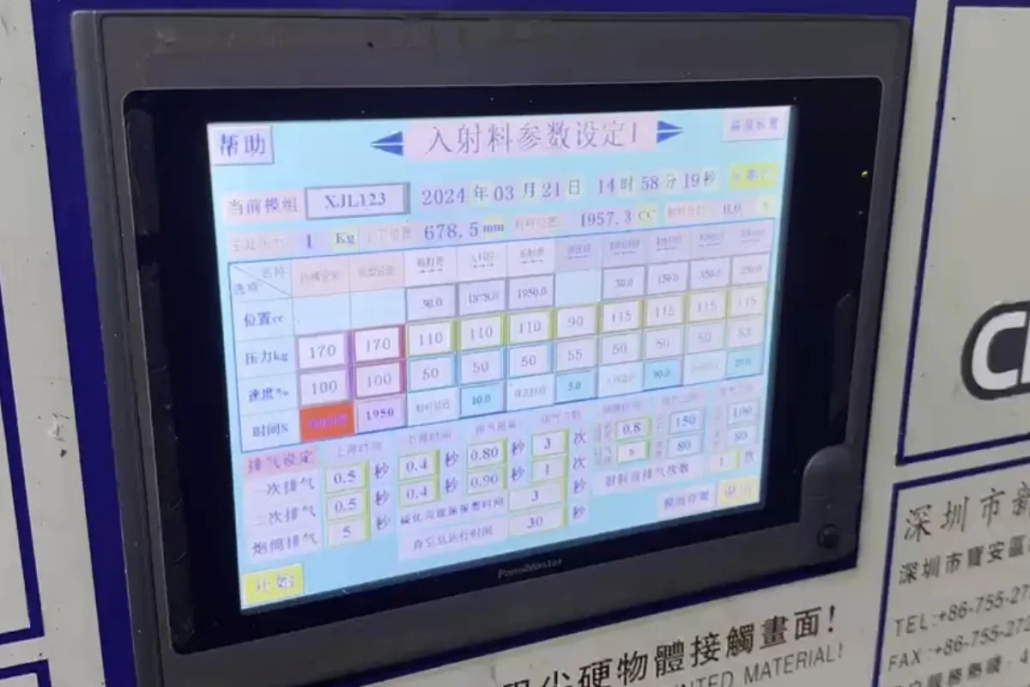

The advent of LSR injection molding necessitated the development of specialized machinery and tooling. These innovations include high-precision dosing systems, which ensure accurate ratios of LSR components, and heated molds that facilitate rapid curing. The machinery also features advanced control systems capable of monitoring and adjusting process parameters in real time, such as temperature, pressure, and injection speed, to optimize the molding process and ensure the consistent quality of the final products.

Automation plays a crucial role in LSR injection molding, with robotic systems often used to handle parts and perform post-molding operations, such as demolding, trimming, and quality inspection. These automated systems enhance production efficiency and reduce the likelihood of human error, leading to higher product consistency and lower production costs.

Material Science and Compound Evolution

Over the years, the materials used in LSR injection molding have evolved significantly. Modern LSR formulations offer enhanced properties like improved heat resistance, greater flexibility, and increased durability. These advancements are largely due to innovations in polymer chemistry, including the development of new silicone elastomer grades and the use of specific additives and fillers.

Additives and fillers in LSR play critical roles in modifying the material’s properties to meet specific application requirements. For example, reinforcing fillers like silica can enhance the mechanical strength of LSR, while color pigments and stabilizers are used to improve the material’s aesthetic and environmental resistance properties.

Technological Advancements and Innovations in LSR Injection Molding

Milestones in LSR Injection Molding Technology

The evolution of LSR injection molding technology has been marked by significant milestones that have progressively enhanced production efficiency, product quality, and design complexity. In the early days, LSR injection molding was limited by manual operations and simple machinery. However, the 1980s and 1990s witnessed a surge in technological advancements, with the introduction of automated dosing systems and computer-controlled injection molding machines, which drastically improved the precision and repeatability of the process.

One of the key milestones was the development of closed-loop control systems in the 2000s, which allowed for real-time monitoring and adjustments during the molding process, significantly reducing defects and enhancing product consistency.

The integration of robotics in the 2010s further automated the process, from loading and unloading molds to post-processing operations, thereby increasing production speed and reducing labor costs.

These advancements have not only improved production efficiency but also expanded the design possibilities for LSR products. With the ability to precisely control the molding process, manufacturers can now produce parts with more complex geometries, tighter tolerances, and better surface finishes. This has opened up new applications in industries like healthcare, automotive, and consumer electronics, where the demands for high-quality and high-performance parts are continuously increasing.

Role of Computer-Aided Engineering (CAE)

Computer-Aided Engineering (CAE) has transformed the LSR injection molding process, from the initial design and simulation stages to optimization and troubleshooting. CAE tools enable engineers to create detailed 3D models of the mold design and simulate the injection molding process, allowing them to predict how the LSR will flow, cure, and behave within the mold. This predictive capability helps in identifying potential issues like air traps, weld lines, or insufficient curing, which can be addressed before the mold is manufactured, saving time and costs.

Case studies in industries such as medical devices and automotive components have demonstrated the benefits of CAE in LSR injection molding. For example, in the medical device industry, CAE has been used to design intricate components like valve seals and catheter tips, optimizing the material flow and curing process to meet stringent quality standards. In the automotive sector, CAE has facilitated the development of complex, multi-functional parts like gaskets and seals, which require precise mechanical properties and tight tolerances.

Materials, Machinery, and Process Advances

Innovations in LSR formulations have significantly expanded the range of applications and improved performance characteristics. New LSR types with enhanced properties, such as increased heat resistance, lower compression set, and greater elongation, have been developed to meet the specific needs of various industries. Additives and fillers have also been refined to improve the mechanical, thermal, and optical properties of LSR, enabling its use in more demanding applications.

On the machinery front, advancements include the development of more sophisticated injection units with better control over injection speed and pressure, dynamic mixing systems that ensure a homogenous mix of the LSR components, and enhanced clamping designs that provide uniform pressure throughout the mold cavity. These improvements have led to more efficient, precise, and reliable LSR injection molding operations, with faster cycle times and reduced material wastage.

Integration with Other Technologies

LSR injection molding has increasingly been integrated with other manufacturing processes, such as overmolding and micro-molding, to create complex and multi-material components. Overmolding, which involves molding LSR over a substrate material like plastic or metal, has enabled the production of parts with combined properties of both materials, such as rigid yet flexible components or parts with integrated sealing and mounting features.

Micro-molding with LSR has allowed the manufacture of extremely small, precise, and detailed components, particularly useful in the medical and electronics industries. This integration has necessitated further innovations in injection molding machinery and tooling, capable of handling the intricacies and precision required for such complex and small-scale productions.

These integrations showcase the versatility of LSR injection molding and its adaptability to meet the evolving demands of the manufacturing industry, enabling the creation of innovative products that combine functionality, durability, and design complexity.

Industry Applications of LSR Injection Molding and Historical Evolution

Medical Industry Evolution

Early uses of LSR in the medical field were limited to non-implantable items like tubing and seals, capitalizing on LSR’s inertness and compatibility with sterilization processes. As LSR technology evolved, it enabled the production of more complex and critical items, such as long-term implantable devices.

A pivotal development was the use of LSR in making advanced prosthetics and organ models, demonstrating LSR’s potential for creating bio-compatible and life-saving innovations.

The shift from external medical devices to implantable solutions marked a significant use of LSR. For example, the creation of LSR-based heart valves and cochlear implants showcased the material’s capability in high-precision, life-critical applications, representing a major leap in medical technology and patient care.

Automotive Industry Transformation

In the automotive sector, initial applications of LSR included simple components like door seals and gaskets, which utilized its durability and resistance to extreme temperatures.

Over time, LSR injection molding expanded into more sophisticated applications, such as ignition cables and LED headlamp seals, due to advancements in material formulations and processing techniques. This evolution reflects LSR’s growing role in enhancing vehicle performance, safety, and longevity.

In addition, The adoption of LSR in high-performance components like turbocharger membranes and vibration control systems illustrates the material’s contribution to automotive engineering advancements. These applications not only leveraged LSR’s thermal stability and mechanical properties but also highlighted its role in improving vehicle efficiency and durability.

Consumer Products Revolution

The consumer goods sector has witnessed a significant transformation, starting from LSR’s use in household items like bakeware and baby products to the development of high-tech wearable devices. The material’s versatility and safety have been crucial in its adoption for diverse applications, from kitchen utensils to waterproof smartwatch components. This transition highlights the adaptability of LSR to meet varying consumer demands and the push for innovative, durable, and user-friendly products.

Challenges and Solutions in LSR Injection Molding

Technical Challenges and Innovations

LSR injection molding, despite its numerous advantages, faces several technical challenges. One of the primary issues has been managing the material’s low viscosity, which, while beneficial for filling intricate molds, can lead to flash and spillage, resulting in material waste and part defects. Innovations to address this include the development of precision mold designs and the integration of advanced process control systems that can regulate injection parameters with high accuracy, minimizing excess material leakage.

Another technical challenge is the need for maintaining consistent material properties, such as viscosity and reactivity, which can vary due to storage conditions or batch differences. To combat this, advancements in material formulation and storage solutions have been developed. For instance, manufacturers have improved the stability of LSR materials, ensuring that they maintain consistent properties over time and are less susceptible to environmental variations.

Additionally, the requirement for high-precision tooling to produce defect-free parts with complex geometries has driven the development of sophisticated mold fabrication technologies. These include the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) to create molds that accurately reflect the intended part design and minimize the risk of manufacturing errors.

Environmental Challenges and Strategic Solutions

Environmental concerns, particularly regarding the sustainability of manufacturing processes, have become increasingly prominent. LSR injection molding, like other manufacturing processes, faces scrutiny over its environmental impact, including the use of non-renewable resources and generation of waste.

To address these issues, the industry has been moving towards more sustainable practices. One approach has been the development of recycling techniques for LSR materials, allowing waste silicone to be repurposed into new products, thereby reducing landfill waste.

Additionally, efforts to minimize the environmental footprint of LSR injection molding have led to the creation of more energy-efficient machinery and processes, significantly lowering the energy consumption and associated carbon emissions of LSR production.

The industry has seen a shift towards the use of bio-based silicone materials, which are derived from renewable resources and offer a more sustainable alternative to traditional silicones. These materials aim to reduce dependency on fossil fuels and decrease the carbon footprint of the LSR injection molding process.

The LSR injection molding industry has faced and continues to tackle a range of technical and environmental challenges. Through continuous innovation and strategic implementation of sustainable practices, the industry is evolving to meet these challenges, enhancing the efficiency and environmental compatibility of LSR injection molding processes.

The Future of LSR Injection Molding

Current Trends and Future Directions

The future of LSR injection molding is shaped by current trends that emphasize automation, precision, and integration with digital technologies. The industry is witnessing a surge in the use of smart manufacturing practices, where LSR injection molding processes are increasingly automated and monitored using sensors and IoT (Internet of Things) technology. This digital transformation enables real-time data collection and analysis, leading to more efficient, flexible, and responsive production lines.

Advancements in materials science are also driving the future of LSR injection molding, with research focusing on developing new LSR formulations that offer enhanced properties, such as improved biocompatibility, higher temperature resistance, and greater elasticity. These innovations are expected to open up new applications in demanding sectors like aerospace and medical devices, where extreme performance criteria are a norm.

Furthermore, the integration of LSR injection molding with additive manufacturing (3D printing) is a burgeoning trend. This combination allows for the rapid prototyping of molds and the production of complex parts that would be challenging or impossible to create using traditional methods, significantly reducing development times and costs.

Potential Growth Areas and Emerging Applications

Emerging applications for LSR injection molding are vast, particularly in the medical and healthcare sector, where the demand for advanced medical devices and wearables continues to grow. LSR’s biocompatibility and mechanical properties make it ideal for applications ranging from long-term implantable devices to single-use surgical instruments.

In the automotive industry, the shift towards electric vehicles (EVs) and autonomous driving technologies is creating new opportunities for LSR, particularly in sealing solutions, sensors, and electronic components that require high performance in challenging environmental conditions.

Consumer electronics is another growth area, with LSR being used to create waterproof seals, soft-touch components, and durable protective cases for a range of devices, including smartphones, tablets, and wearable technology.

Impact of Sustainability and Recycling

Sustainability and environmental concerns are increasingly influencing the LSR injection molding industry. There is a growing emphasis on developing eco-friendly LSR formulations that are recyclable or derived from renewable resources. The industry is also focusing on reducing waste and improving the energy efficiency of the molding process.

Recycling of LSR products is a challenge due to the cross-linked nature of silicone, which makes it difficult to remelt and reform. However, research is ongoing to find viable methods for recycling or repurposing silicone waste, such as downcycling into secondary products or energy recovery.

The future of LSR injection molding is likely to be heavily influenced by the industry’s ability to align with circular economy principles, reducing the environmental footprint of products throughout their lifecycle, from production to disposal.

Conclusion

The history of Liquid Silicone Rubber (LSR) and injection molding is marked by significant advancements that revolutionized manufacturing. Beginning with the inception of injection molding in the 19th century and the subsequent development of silicone rubbers in the 20th century, these technologies have evolved to meet the growing demands of various industries.

LSR, known for its exceptional properties, combined with the precision and efficiency of injection molding, has enabled the production of durable, complex, and high-quality products across medical, automotive, and consumer sectors.

This evolution reflects the continuous innovation and adaptation within the manufacturing field, showcasing the enduring importance and impact of LSR and injection molding in modern industry. As we move forward, these technologies are set to drive further advancements, shaping the future of manufacturing with ongoing improvements in materials, processes, and applications.